the regular rockwell hardness test indenter is|rockwell hardness test explained : vendor A Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the diameter of the indentation only 0.019 inch, which is barely visible. The . WEB28 de dez. de 2023 · Palpite no futebol europeu é na APWin!! Dessa vez, um palpite para Crystal Palace x Brentford, em jogo válido pela 20ª rodada do Campeonato Inglês.. Na sua última partida, o Crystal Palace perdeu por 2 x 1 para o Chelsea com gol de Michael Olise ao minuto 45. Na sua última partida, o Brentford perdeu por 1 x 4 para o .

{plog:ftitle_list}

A Lotofácil também tem um bolão disponível para apostas em grupo. O preço mínimo cobrado pela Caixa nessa modalidade é de R$ 10, e as cotas de cada . Ver mais

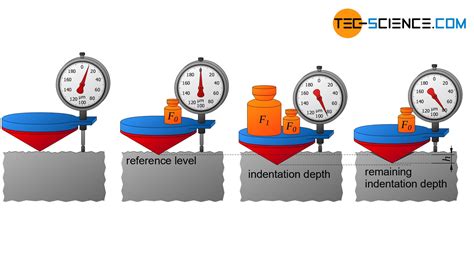

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured. In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined .

While the HRC scale uses a maximum of 0.2 millimeter (100 Rockwell points) penetration, the HRB and other regular scales use a ball indenter because they test softer materials and have a maximum depth of .The Rockwell Hardness Test uses a diamond cone or hardened steel ball to indent the material being tested. Each time a test is performed, two loads are applied to the sample. First, the indenter is forced into the test material under .A Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the diameter of the indentation only 0.019 inch, which is barely visible. The . The instrument, called an indenter, is pressed into the sample for a standardized length of time (a number of seconds), and with a specific load (force) behind it. When the indenter is pressed into the material, it deforms .

rockwell hardness testing equipment

rockwell hardness tester chart

Indenter shape and material: Depending upon the specific Rockwell method employed, the indenter is either a diamond cone (with a cone angle of 120°) or a hard metal ball (with various diameters depending on the method).

Rockwell Hardness ASTM D785, ISO 2039. The Rockwell Hardness test is a widely used method for measuring the hardness of various materials. It measures the depth of .The Rockwell hardness test uses a spherical steel indenter; hardness is determined from the penetration depth. For Rockwell hardness, there are two conditions that are used for polymers. .

rockwell hardness test methodology

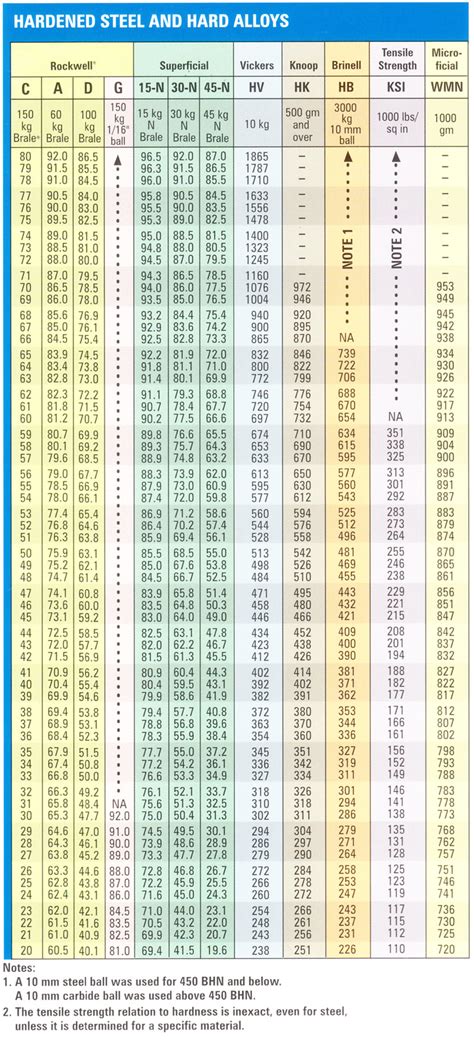

The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel .Indenter Shrouds; Jominy Fixtures; Vise Fixtures; X-Y Stages; Updates / Upgrades. . Guides to Hardness Testing. Hardness Conversion for Rockwell C Scale or High Hardness Range . Regular Rockwell Testing. In this test .All rockwell diamond indenters are performance-tested on a master Rockwell hardness tester in our environmentally controlled ISO 17025 standardizing laboratory. The indenters are then compared to a 0-0 master indenter within a . In the Rockwell hardness test, an indenter is pressed into the material to be tested. The indentation depth serves as a measure of the hardness! The measuring process of the Rockwell test is carried out in three .

rockwell hardness test indenter

Regular Rockwell Hardness Test where the minor load is 10 kgf and major load is 60, 100, or 150 kgf. . Rockwell Scale Symbol: Type of Indenter/Diameter in case of Ball: Minor Load, N (kgf) Major Load, N (kgf) Typical use: 15N: Spheroconical diamond: 29.42(3) 147.1 (15) The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters. . This anvil is only used with the 15 T or 30 T Rockwell scales. Using a diamond indenter with a diamond spot .The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell hardness tester: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y Polymer/Plastic ScalesRegular Rockwell hardness test: In this test, a load of 60, 100, or 150 kg is applied to the surface of the material for a few seconds, depending on the hardness of the material. . The Rockwell hardness test uses an indenter, typically a diamond cone or steel ball, that is pressed into the surface of the material being tested. The depth of .

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method.Rockwell Regular hardness =130 0 002 − h, HRN HRTW Rockwell Superficial hardness =100 0 001 − h, 4.2 The following is an example of the designation of Rockwell hardness. EXAMPLE 70 HR 30 T W indication of type of ball used, W = Tungsten carbide composite Rockwell scale symbol (see Tables 1 or 2) Rockwell hardness value Rockwell hardness symbolRegular, superficial and combination units available to operate in all Rockwell scales in regular and superficial Rockwell ranges. Available in several capacities. The Indentron Series hardness testers feature an innovative cantilevered indenter configuration that eliminates frictional inconsistencies typical of competitive testing systems.

An indentation hardness test using a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter, under specified conditions, into the surface of the material under test, and to measure the difference in depth of the indentation as the force on the indenter is increased from a specified preliminary .The test method for Rockwell testing (ASTM E-18-08a) only allows the use of tungsten carbide ball indenters. AMETEK makes a variety of Newage indenters and indenter accessories. We recommend that you contact us , for assistance in specifying and ordering an indenter for your Rockwell , Brinell or Microhardness application.

rockwell hardness test explained

Hardness tests can be defined as forcing an hardness testing indenter of a specified size, shape, and material into the surface of a test piece to obtain a hardness value. . A582143 - Rockwell Regular Kit – includes Rockwell C Indenter, 25 HRC, 63 HRC and 80 HRB test blocks; A58239 - Rockwell Superficial Kit – includes Rockwell N Indenter .

aggregate impact test experiment

6 - Newage Hardness Testing Versitron Rockwell Hardness Testing System 2. TEST METHOD 2.1 ASTM E-18: Rockwell Hardness Testing This tester operates according to ASTM E-18 standard in all particulars. It is used by virtually every large automotive, aerospace and defense manufacturer in the nation. 2.2 Top-loading and Test Surface Referencingcorrect scale to ensure an accurate Rockwell test in necessary. The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the .

Rockwell Hardness Testing System. . indenter is an indenter shroud. The purpose of the shroud is to sense the position of the indenter rela-tive to the test surface when the preload has been applied. Should the test specimen deflect under . * The interchangable regular and superficial test heads can be ordered as using part no. BT1302RS .

aggregate impact test is code

Ordinary versus superficial In reality, there are two separate kinds of Rockwell test procedures. The Regular method and the Superficial method are these. The Regular technique is often referred to as the Rockwell method (AKA Super .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method . Regular Rockwell hardness scale chart. Rockwell Scale Symbol: Type of Indenter Diameter in case of Ball: Minor Load: Major Load: Typical use: HRA: Spherical diamond: 98.07 N (10 kgf) 588.4 N (60 kgf)Metallic materials — Rockwell hardness test — Part 1: Test method 1 Scope This part of ISO 6508 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic materials and is applicable to stationary and portable hardness testing machines.

Rockwell Hardness Testing calibration procedures mandate the use of Diamond Indenters that are verified for geometrical and performance standards, per ASTM and ISO requirements by an accredited laboratory. Each Indenter is assigned a certificate of compliance assuring traceability for that indenter. . HRA Scale - Carbide Test Diamond Indenter .

Main Hardness Tester, Diamond HRC Rockwell Indenter, HRB 1/16" Diameter Hard Alloy Steel Ball Indenter, Large Testing Flat Anvil, Medium Testing Anvil and V-shaped Testing Anvil (Medium sized), Standard Hardness Blocks x3, Accessory Case, Dust-Proof Cover, Instruction Manual and Certification/Warranty card . The regular scale Rockwell .It is critical to have a precise and accurate indenter configuration for reliable and dependable Rockwell® hardness testing. A minor deviation in the form of flats, peaks or poor surface finish from the true contour (120˚ including angle, 0.2 mm radius) will result in inaccurate and unreliable hardness readings.The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters. . This anvil is only used with the 15 T or 30 T Rockwell scales. Using a diamond indenter with a diamond spot .The Rockwell hardness test is an essential tool in material science, offering a fast and trustworthy way to measure how hard materials are, with a special focus on metals.This technique gauges how deeply an indenter presses into a material under a heavy load compared to its penetration under a lighter one.

Ernst AT-130 Economical Regular & Superficial Rockwell Hardness Testers. . since the operator cannot contact the indenter with the test sample and shifting of large parts under load is prevented by the clamping - both common causes of breakage that can cost hundreds of dollars a pop. . Ernst AT130 Superficial Rockwell Hardness Tester, N .correct scale to ensure an accurate Rockwell test in necessary. The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the .

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials.

aggregate impact test is code pdf

aggregate impact test lab manual

webCadastre-se na Deezer de graça e ouça Diego Thug: discografia, top músicas e playlists.

the regular rockwell hardness test indenter is|rockwell hardness test explained